Industrial transformers are the backbone of modern power distribution systems. Whether it’s manufacturing plants, commercial facilities, or heavy industries, transformers ensure stable voltage, uninterrupted power supply, and safe operations. However, without proper industrial transformer maintenance, even the most robust transformer can suffer premature failure.

At MSC Transformers, we often see cases where simple maintenance negligence leads to costly downtime, expensive repairs, or complete transformer replacement. The good news? With the right transformer maintenance best practices, you can easily double the lifespan of your industrial transformer while improving performance and safety.

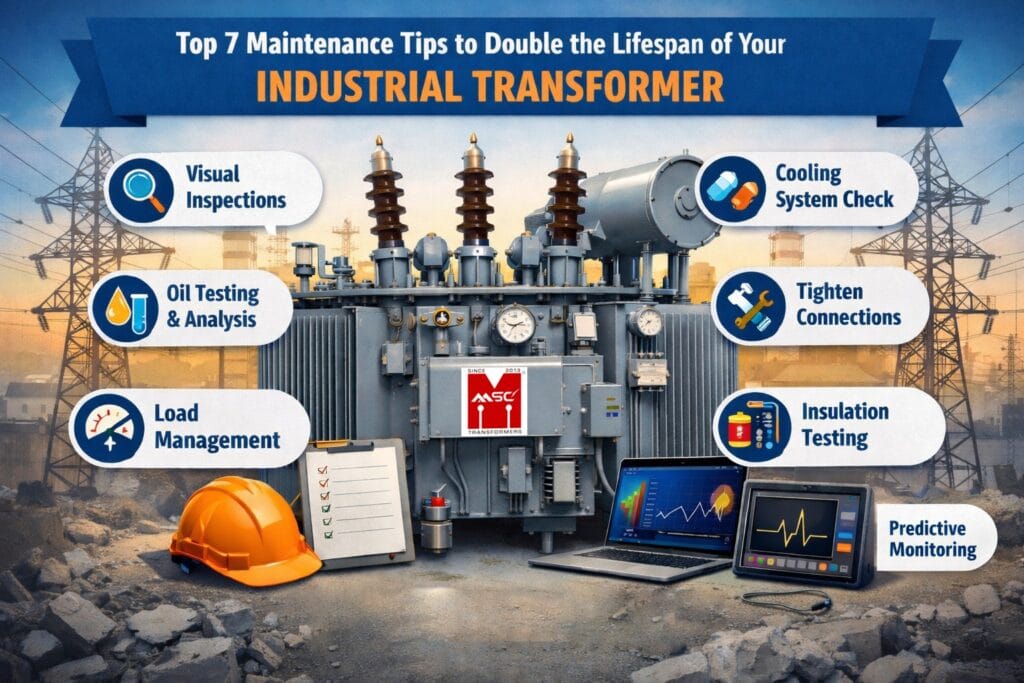

In this blog, we share the top 7 proven maintenance tips every industry should follow to maximize transformer life and efficiency.

Regular Visual Inspection – Your First Line of Defense

One of the most basic yet powerful industrial transformer maintenance tips is regular visual inspection.

What to Check:

- Oil leaks around gaskets and bushings

- Rust or corrosion on the tank

- Loose connections and damaged cables

- Abnormal noise or vibration

- Discoloration due to overheating

Early detection of these issues prevents minor faults from turning into major failures. A weekly or monthly visual inspection can save lakhs in repair costs.

MSC Transformers recommends maintaining a simple inspection checklist for operators and maintenance teams.

Transformer Oil Testing & Analysis

For oil-filled transformers, oil is both an insulator and a coolant. Poor oil quality is one of the leading causes of transformer breakdowns.

Essential Oil Tests:

- Dielectric Breakdown Voltage (BDV)

- Moisture content

- Acidity level

- Dissolved Gas Analysis (DGA)

Regular oil testing helps identify:

- Internal arcing

- Overheating

- Insulation deterioration

This form of power transformer maintenance allows predictive action before failures occur, significantly increasing transformer lifespan.

Maintain Proper Load Management

Overloading is a silent transformer killer.

Operating your transformer beyond its rated capacity:

- Accelerates insulation aging

- Increases oil temperature

- Causes winding damage

Best Practices:

- Monitor load regularly

- Avoid peak-time overloads

- Upgrade transformer capacity if load demand increases

Proper load management is a crucial part of transformer preventive maintenance and directly impacts long-term reliability.

Ensure Effective Cooling System Performance

Heat is the biggest enemy of transformers. Even a small rise in operating temperature can drastically reduce insulation life.

Cooling System Maintenance Includes:

- Cleaning radiators and cooling fins

- Checking fans and pumps

- Ensuring free air circulation

- Removing dust, oil, or debris buildup

Whether it’s ONAN, ONAF, or OFAF cooling, keeping the system efficient ensures optimal transformer performance and longevity.

Tightening & Electrical Connection Checks

Loose connections increase resistance, which leads to:

- Excessive heating

- Voltage drops

- Energy losses

Periodic tightening of:

- Terminal connections

- Bus bars

- Earthing connections

…helps prevent hotspots and improves operational efficiency.

This step is often overlooked but is a critical part of industrial transformer maintenance best practices.

Insulation Resistance & Winding Health Tests

Transformer insulation degrades over time due to heat, moisture, and electrical stress.

Key Tests:

- Insulation Resistance (IR) test

- Polarization Index (PI)

- Winding resistance test

These tests help assess:

- Moisture ingress

- Insulation aging

- Winding integrity

Regular testing ensures early fault detection and prevents sudden transformer failure.

Adopt Predictive Maintenance & Health Monitoring

Modern industries are shifting from reactive maintenance to predictive maintenance.

Advanced Monitoring Includes:

- Online temperature sensors

- Oil level indicators

- Gas detection relays

- Load and voltage monitoring systems

Using transformer health monitoring, industries can:

- Predict failures

- Reduce unplanned downtime

- Extend transformer lifespan significantly

At MSC Transformers, we strongly recommend combining traditional maintenance with smart monitoring for maximum reliability.

Why Proper Maintenance Matters More Than You Think

Neglecting industrial transformer maintenance can result in:

- Unexpected shutdowns

- Production losses

- Safety hazards

- Expensive transformer replacements

On the other hand, a well-maintained transformer can easily last 30–40 years with consistent performance.

Why Choose MSC Transformers?

As a trusted industrial transformers manufacturer, MSC Transformers designs and supplies transformers built for durability, efficiency, and long-term reliability. Our transformers are engineered to support:

- Easy maintenance

- High thermal endurance

- Superior insulation systems

- Industrial-grade performance

We also guide our clients with best maintenance practices to ensure maximum return on investment.

Industrial transformers are long-term assets, not short-term equipment. By following these 7 industrial transformer maintenance tips, you can:

- Double transformer lifespan

- Improve efficiency

- Reduce downtime

- Lower maintenance costs

From routine inspections to predictive health monitoring, proactive maintenance is the key to reliable power systems.

If you are looking for high-quality industrial transformers backed by expert support, MSC Transformers is your trusted partner in power reliability.

Industrial transformers are the backbone of modern power distribution systems. Whether it’s manufacturing plants, commercial facilities, or heavy industries, transformers ensure stable voltage, uninterrupted power supply, and safe operations. However, without proper industrial transformer maintenance, even the most robust transformer can suffer premature failure.

At MSC Transformers, we often see cases where simple maintenance negligence leads to costly downtime, expensive repairs, or complete transformer replacement. The good news? With the right transformer maintenance best practices, you can easily double the lifespan of your industrial transformer while improving performance and safety.

In this blog, we share the top 7 proven maintenance tips every industry should follow to maximize transformer life and efficiency.

Regular Visual Inspection – Your First Line of Defense

One of the most basic yet powerful industrial transformer maintenance tips is regular visual inspection.

What to Check:

- Oil leaks around gaskets and bushings

- Rust or corrosion on the tank

- Loose connections and damaged cables

- Abnormal noise or vibration

- Discoloration due to overheating

Early detection of these issues prevents minor faults from turning into major failures. A weekly or monthly visual inspection can save lakhs in repair costs.

MSC Transformers recommends maintaining a simple inspection checklist for operators and maintenance teams.

Transformer Oil Testing & Analysis

For oil-filled transformers, oil is both an insulator and a coolant. Poor oil quality is one of the leading causes of transformer breakdowns.

Essential Oil Tests:

- Dielectric Breakdown Voltage (BDV)

- Moisture content

- Acidity level

- Dissolved Gas Analysis (DGA)

Regular oil testing helps identify:

- Internal arcing

- Overheating

- Insulation deterioration

This form of power transformer maintenance allows predictive action before failures occur, significantly increasing transformer lifespan.

Maintain Proper Load Management

Overloading is a silent transformer killer.

Operating your transformer beyond its rated capacity:

- Accelerates insulation aging

- Increases oil temperature

- Causes winding damage

Best Practices:

- Monitor load regularly

- Avoid peak-time overloads

- Upgrade transformer capacity if load demand increases

Proper load management is a crucial part of transformer preventive maintenance and directly impacts long-term reliability.

Ensure Effective Cooling System Performance

Heat is the biggest enemy of transformers. Even a small rise in operating temperature can drastically reduce insulation life.

Cooling System Maintenance Includes:

- Cleaning radiators and cooling fins

- Checking fans and pumps

- Ensuring free air circulation

- Removing dust, oil, or debris buildup

Whether it’s ONAN, ONAF, or OFAF cooling, keeping the system efficient ensures optimal transformer performance and longevity.

Tightening & Electrical Connection Checks

Loose connections increase resistance, which leads to:

- Excessive heating

- Voltage drops

- Energy losses

Periodic tightening of:

- Terminal connections

- Bus bars

- Earthing connections

…helps prevent hotspots and improves operational efficiency.

This step is often overlooked but is a critical part of industrial transformer maintenance best practices.

Insulation Resistance & Winding Health Tests

Transformer insulation degrades over time due to heat, moisture, and electrical stress.

Key Tests:

- Insulation Resistance (IR) test

- Polarization Index (PI)

- Winding resistance test

These tests help assess:

- Moisture ingress

- Insulation aging

- Winding integrity

Regular testing ensures early fault detection and prevents sudden transformer failure.

Adopt Predictive Maintenance & Health Monitoring

Modern industries are shifting from reactive maintenance to predictive maintenance.

Advanced Monitoring Includes:

- Online temperature sensors

- Oil level indicators

- Gas detection relays

- Load and voltage monitoring systems

Using transformer health monitoring, industries can:

- Predict failures

- Reduce unplanned downtime

- Extend transformer lifespan significantly

At MSC Transformers, we strongly recommend combining traditional maintenance with smart monitoring for maximum reliability.

Why Proper Maintenance Matters More Than You Think

Neglecting industrial transformer maintenance can result in:

- Unexpected shutdowns

- Production losses

- Safety hazards

- Expensive transformer replacements

On the other hand, a well-maintained transformer can easily last 30–40 years with consistent performance.

Why Choose MSC Transformers?

As a trusted industrial transformers manufacturer, MSC Transformers designs and supplies transformers built for durability, efficiency, and long-term reliability. Our transformers are engineered to support:

- Easy maintenance

- High thermal endurance

- Superior insulation systems

- Industrial-grade performance

We also guide our clients with best maintenance practices to ensure maximum return on investment.

Industrial transformers are long-term assets, not short-term equipment. By following these 7 industrial transformer maintenance tips, you can:

- Double transformer lifespan

- Improve efficiency

- Reduce downtime

- Lower maintenance costs

From routine inspections to predictive health monitoring, proactive maintenance is the key to reliable power systems.

If you are looking for high-quality industrial transformers backed by expert support, MSC Transformers is your trusted partner in power reliability.